What is Anodized? How to Make an Anodized Aluminum Profile?

The anodized process is a process made of hard aluminum. Anodized service is required within the scope of this service, so that aluminum can become as functional as steel. There is a side of steel that significantly increases the benefit to the user. Therefore, it is important to underline that it is highly preferred and attracts great attention.

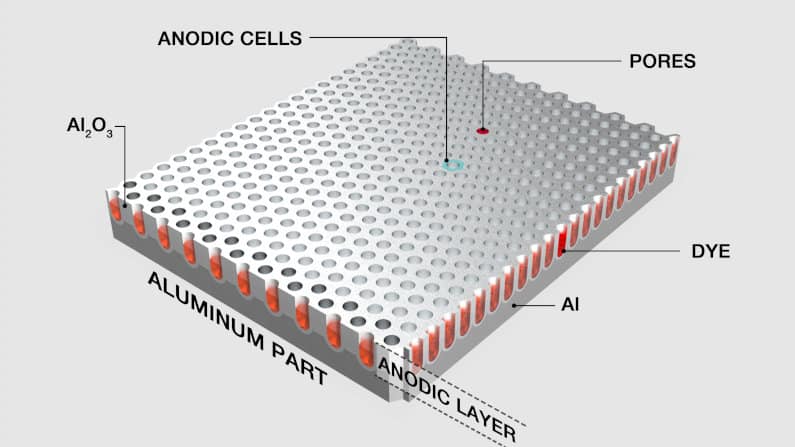

It is possible to describe the anodized process as depositing the aluminum in the electrolyte bath. It is possible to explain the electrolyte bath as a kind of sulfuric acid bath. The process is carried out by passing a simple electric current through the acid solution. This process is known to give results with greater performance. The fact that hard aluminum is more useful than steel and that it is an element that can be found more easily has a great effect. With this service, aluminum, which draws attention with its lightweight, becomes more insulating.

Types of Anodized Aluminum Profiles

The anodized aluminum profile service, which covers all three services under its name, includes the basic anodized service in the first place. This service, also known as the classical anodized service, allows the aluminum to be shaped more easily. In addition, it increases the insulation and helps the area where it is used to become more resistant to heat and light. It is also useful to underline that it has a structure that does not deteriorate for many years.

The normal version of anodized service is achieved by coating the original aluminum sheets with a thin oxide. This service, also known as coating with rust, makes the material more resistant to scratches, bumps, and other accidents. In addition to allowing use for many years, it does not require frequent replacement, renewal, or maintenance.

The hard anodized process, which is another type of anodized profile, is performed by cooling the acid solution to the freezing point of the water. In addition, the electric current is greatly increased compared to the first. It is known that a thicker aluminum oxide layer is formed in this way. In addition, holes and cracks on the surface are penetrated. This can help create a better image. It should also be underlined that it also allows a brown or black color to be taken.

Where are Anodized Aluminum Profiles Used?

There are many areas where anodized aluminum profiles can be used. It is also useful to underline that the interest shown in this service, which offers features such as ease of use, durability, and insulation in almost every field, is very intense. Considering the benefits such as having a professional infrastructure, low frequency of replacement, fast production, providing a beautiful appearance, and being able to be arranged as desired, it offers serious convenience and comfort to people. Therefore, it is possible to say that it has entered almost every field.

The surfaces on which it is used, especially after the hard anodized process;

- Mold surfaces,

- Areas where risky liquids with corrosive properties are used,

- machine apparatus,

- surface apartments,

- Aviation,

- defense industry

covered areas such as In all of these areas, it is not easily bent and bent, not easily rusted, and its durability has been of great benefit. It should not be forgotten that these areas are risky areas and thanks to this service, products with very high durability are produced and the cost of steel is significantly reduced. At this point, it is of great importance not to ignore the advantage it provides in terms of cost. This situation, which provides a great advantage in providing customer satisfaction, makes many companies more profitable.